Greeting

As our company name implies, we at Think Laboratory have been creating new products that have never existed in the world by “THINK,” the act of thinking. The gravure cylinder making equipment that we have manufactured since our establishment has been installed by many customers throughout Japan and overseas. Gravure printing is used in Japan and many other countries, especially for food packaging, as a method that enables high-speed, high-quality printing on a wide variety of substrates. In the field of printing, the demand for packaging is increasing worldwide.

As our company name implies, we at Think Laboratory have been creating new products that have never existed in the world by “THINK,” the act of thinking. The gravure cylinder making equipment that we have manufactured since our establishment has been installed by many customers throughout Japan and overseas. Gravure printing is used in Japan and many other countries, especially for food packaging, as a method that enables high-speed, high-quality printing on a wide variety of substrates. In the field of printing, the demand for packaging is increasing worldwide.

Our cylinder making system “NewFX series”, which combines laser cylinder making and transport by robot, differentiates itself from conventional systems in terms of productivity and high image quality, and we have shipped more than 100 sets in total. This system is ideal for gravure printing using water-based ink, which requires high line counts and shallow cell depth cylinder making, and has been further improved and evolved over the years. The system can also be combined in-line with an automatic inspection system for further labor savings.

We are also expanding the possibilities of gravure printing by using laser gravure cylinder production technology to manufacture cylinders for printing electronic components and to apply DLC coating, which is more abrasion resistant than chrome plating, to cylinders.

We have developed the world’s first water-based inkjet printing press for flexible packaging as a solution to the recent trend toward high-mix, small-lot printing, short delivery times, and a shortage of operators. Our inkjet printers using odor-free water-based ink can print at a high resolution of 1200 dpi on commercially available film substrates as wide as 1100 mm without primer treatment.

The “BMF” (Business Model Factory), located in the headquarters, is equipped with a water-based inkjet printer “FXIJ”, a solvent free laminator, a slitter, a bag-making machine, etc., and shows how the actual manufacturing of packaging, from printing to post-processing, is done in a single pass with a minimum configuration of equipment. The digital printing process, which does not use printing cylinder, is a conventional printing method. Digital printing, which does not use plates, is a new field that is not bound by conventional boundaries, and its possibilities are expanding. In addition to this, we are also practicing having in-house facilities for machining mechanical parts and manufacturing water-based inks to reduce costs, improve product quality, and shorten the cycle of product improvement. Think Laboratory will continue to challenge innovation and contribute to society.

Think Laboratory Co., Ltd. President

Kaku Shigeta

Company Profile/History

Company Profile

| Company name | Think Laboratory Co., Ltd. |

|---|---|

| Founded | November 1, 1966 |

| Capital | 47,25 million yen |

| Location | 【Head Office Factory】 1201-11 Takata, Kashiwa City, Chiba 277-0861 Japan TEL +81-(0)4-7143-6760 (Representative) FAX +81-(0)4-7146-0566 【Second Factory】 610-1 Toyofuta Kashiwa City, Chiba 277-0872 Japan TEL +81-(0)4-7147-8687 【Osaka Factory】 3-9-41 Mizuhai, Higashi Osaka-shi, Osaka 578-0921 Japan TEL +81-(0)72-961-4020 FAX +81-(0)72-961-4019 |

| Number of employees | 140 people |

| Business content | ・ Development, design, manufacture and sale of automated laser gravure plate making system New FX ・Development, manufacture and sale of photosensitive solutions and other consumable chemicals used in the above device ・Microprinting for electronic parts ・Production and sale of molding rolls |

| Departments | 【Planning】Domestic and overseas system proposals 【Manufacturing】Parts manufacturing by large machine tools 【Assembly】Machine assembly, installation maintenance 【Electric】Software and robots related 【Design】Machine design, new machines development 【Development】Chemicals development 【Procurement】Related material procurement, parts management 【General Affairs/Accounting】Employee Management, Financial Management |

| Board members | Chairman Tatsuo Shigeta President Kaku Shigeta Director Shintaro Sugawara Director Mitsuru Yamaguchi Executive Officer Ryota Morisaki Executive Officer Eiji Takahashi Executive Officer Etsuji Yamagami Executive Officer Takayuki Yamada Executive Officer Takahisa Chiba Corporate Auditor Kazuo Nagatsuma |

| Customers | 250 companies in 38 countries |

History

| 1966 | Think Laboratory Co., Ltd. established in Osaki Shinagawa-ku, Tokyo |

|---|---|

| 1970 | Moved to Kashiwa city, Chiba. |

| 1977 | Gravure plate making machine “System 77” released. |

| 1982 | DRUPA first exhibition. “Boomerang” using an overhead traveling crane presented. |

| 1983 | Launched laser direct drawing type direct gravure plate making machine “LaserStream”. |

| 1990 | Head office moved to the current location (Kashiwa City Takada). The former head office became Second Factory. |

| 2002 | Established the Osaka factory (Higashiosaka city). Expansion of service to the Kansai area. |

| 2003 | Launched “Laser stream FX” equipped with 830 nm semiconductor laser. |

| 2006 | Supplied gravure cylinders for plasma display electrode printing to Samsung SDI company. |

| 2010 | Announced “NewFX” transporting cylinder by robot which allowed to half the installation area. |

| 2016 | Presented FXIJ water-based ink jet printer for flexible packaging |

Access

Main Factory (1201-11 Takata, Kashiwa City, Chiba 277-0861)

■ When using a car

About 10 minutes from Joban Expressway 【Kashiwa IC】

■ When using a train

① About 10 minutes by taxi from Tsukuba Express 【Nagareyama Ootaka no Mori Station】

②About 10 minutes by taxi or bus from Tsukuba Express 【Kashiwanoha Campus Station】West Exit

※ Bus: To Kashiwa station West Exit, Get off at [Kinzoku Kogyo Danchi-mae stop]

③ About 10 minutes by taxi or from JR [Kashiwa Station] West Exit Terminal

※ Bus: To Kashiwanoha Park / To National Cancer Center / Kashiwanoha Campus Station, Get off at [Kinzoku Kogyo Danchi-mae stop]

Osaka Factory (3-9-41 Mizuhai, Higashi Osaka-shi Osaka 578-0921)

■ When using a car

About 10 minutes from Hanshin Expressway No. 13 Higashi Osaka line [Mizuhai IC]

■ When using a train

About 8 minutes on foot from Kintetsu Keihanna Line [Yoshida Station] (about 650 m)

Environmental Initiatives

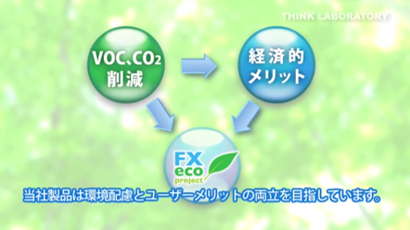

We have been researching and developing the environmental improvement with the process automatization and creating our systems in collaboration with a lot of companies.

As a result, we managed to reduce the amount of used inks up to 20% with new technology applied to our products.

Furthermore, along with the latest high-speed image processing software, by development of the water-based inkjet printer FXIJ we reached more safety and work environment comfort.

Moreover, we are using natural energy from solar panels installed on the rooftop of the factory.